Defender Tubular Services is an oilfield services company based in Texas, USA, specializing in cleaning and maintaining oil drilling pipes. The company operates across multiple sites in the eastern United States, where accurate pipe tracking is critical for safety, compliance, and operational efficiency.

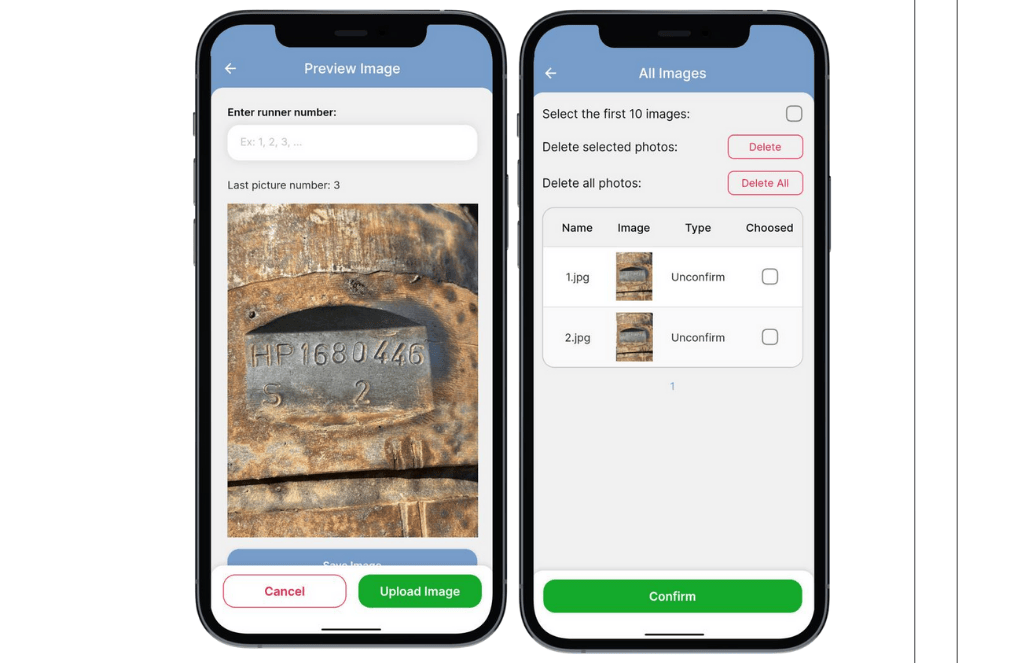

The team developed a computer vision–based OCR system capable of detecting, reading, and validating serial numbers directly from pipe surfaces.

Key solution components include:

-

OCR models trained to recognize serial numbers under real-world conditions

-

AI-based validation to detect and correct potential recognition errors

-

Desktop application for on-site usage

-

Real-time data synchronization with Excel for tracking and reporting

-

Cloud deployment to ensure scalability and reliability

A Proof of Concept (PoC) was delivered rapidly to validate feasibility before full-scale development.

Results:

-

85% recognition accuracy, compared to 30% with the traditional manual method

-

53% faster logging process for serial number recording

-

70% reduction in data entry errors

-

PoC delivered in 2 weeks

-

Full AI system developed and deployed in 8 weeks

The solution significantly improved operational efficiency while reducing human error and manual workload.

Key Business Impact:

-

Digitized a critical operational process

-

Improved data accuracy and traceability

-

Reduced manual workload at oil rig sites

-

Enabled real-time access to maintenance data

-

Established a scalable AI foundation for future expansion